#plastic recycling License in india

Explore tagged Tumblr posts

Text

How To Start a Plastic Waste Import Business In India

How To Start a Plastic Waste Import Business In India. (2023, May 9). FactsTea. https://factstea.com/how-to-start-a-plastic-waste-import-business-in-india/ Introduction: India is one of the largest consumers of plastic in the world, with a growing demand for plastic products across different industries. However, the country is facing a massive challenge of plastic waste management, with a large…

View On WordPress

#plastic recycling certification#plastic recycling certification in india#plastic recycling License#plastic recycling License in india#plastic waste management authorization#plastic waste management registration#plastic waste management registration online#plastic waste recycling license

0 notes

Text

Vikas Lifecare Limited Joins Forces with DRDO for Breakthrough Biodegradable Plastics Technology

In a landmark development, Vikas Lifecare Limited (VLL), a distinguished name in polymer and specialty additive manufacturing, has taken a significant step toward sustainability. The company announced a strategic collaboration with the Advanced Systems Laboratory (ASL) of the Defence Research and Development Organisation (DRDO), Ministry of Defence, Government of India. This agreement, signed on December 16, 2024, marks a milestone in the advancement of biodegradable plastics technology, with the potential to revolutionize the fight against plastic pollution.

This partnership centers around a cutting-edge innovation by DRDO—a technology for producing biodegradable granules designed to replace conventional single-use polyethylene bags. Known primarily for its defense and strategic research, DRDO has ventured into civilian domains with high societal impact. Through this collaboration, Vikas Lifecare Limited is poised to play a pivotal role in scaling the application of this groundbreaking solution for environmental sustainability.

The biodegradable granules developed by DRDO present significant economic and ecological advantages. These granules offer an affordable alternative to traditional polyethylene bags, catering to the rapidly growing demand for sustainable packaging solutions. As the Indian plastic packaging market is expected to grow from USD 21.77 billion to USD 25.35 billion by 2029, this innovation aligns seamlessly with industry trends. Additionally, these granules promise long-term cost savings by reducing environmental clean-up expenses, thereby bolstering efforts toward a circular economy.

Under the agreement, Vikas Lifecare Limited has been granted a non-exclusive license to manufacture these biodegradable granules in India and market them both domestically and globally over the next decade. DRDO has ensured a smooth technology transfer by providing comprehensive support, including detailed specifications, material sourcing information, testing protocols, and all necessary documentation. This collaborative venture underscores a strong commitment to environmental stewardship and sets a benchmark for corporate contributions to sustainable development.

Vikas Lifecare Limited has long been a proponent of environmental responsibility. The company’s initiatives in recycling plastic waste to fulfill Extended Producer Responsibility (EPR) mandates have already positioned it as a key player in the circular economy. This latest move into biodegradable plastics technology is a logical extension of its sustainability mission, aiming to address environmental concerns more holistically.

Beyond its achievements in biodegradable plastics, Vikas Lifecare Limited has built a robust portfolio across various industries. The company specializes in manufacturing polymer and rubber compounds, upcycled materials, and specialty additives, making significant contributions to the reduction of industrial and post-consumer waste. Furthermore, VLL has diversified into the business-to-consumer (B2C) market, introducing FMCG, agro, and infrastructure products. The company also ventured into entertainment with a film production arm, showcasing its versatility and innovative spirit.

VLL’s subsidiary, Genesis Gas Solutions Pvt. Ltd., further exemplifies its forward-thinking approach. Genesis is a leader in smart gas metering, commanding a substantial share of the domestic gas metering market in India. A joint venture with Indraprastha Gas Limited aims to establish a state-of-the-art manufacturing plant for advanced gas meters by FY 2024-25, using cutting-edge technology from global leaders and indigenous software solutions.

Commenting on this transformative partnership, Sundeep Kumar Dhawan, Managing Director of Vikas Lifecare Limited, expressed his optimism. "This collaboration with DRDO represents a major step forward in our journey toward sustainability. By embracing innovative biodegradable technologies, we reaffirm our commitment to reducing environmental impact and contributing to a cleaner, greener future."

Vikas Lifecare Limited continues to demonstrate its dedication to driving change, leveraging technology and innovation across diverse sectors. As the world shifts toward more sustainable practices, the company’s collaboration with DRDO solidifies its position as a trailblazer in the quest for eco-friendly solutions.

0 notes

Text

If you need to obtain EPR Certification in India, then ASC Group is a reputed consultancy firm that provides services to companies related to compliance, license & certification. They help in EPR registration for which is compulsory for organizations involved in the manufacturing of, importing or exporting of E waste, plastics or in the business of recycling of such waste in India as per the Companies under E-Waste (Management) and Plastic Waste Management Rules.

#Epr Registration Certificate#EPR Registration#EPR Certificate#Epr Certificate For Import#EPR authorization#EPR Registration online#EPR Registration fees#EPR Registration process#EPR Certificate online#epr certification#epr license#epr license online#epr license for import#epr registration consultant#epr registration for e waste#CPCB EPR Registration online#CPCB plastic waste Registration#EPR Certification in India

0 notes

Text

Global Propane Dehydrogenation to Propylene Market, Market Size, Market Share, Key Players | BIS Research

Thermoset plastics, known for their excellent mechanical strength, chemical resistance, and durability, have long been integral in industries like automotive, aerospace, electronics, and construction. However, their primary drawback has been that, once cured, they are difficult to recycle. This has posed a significant environmental challenge, as traditional thermosets end up in landfills, contributing to plastic waste.

The global propane dehydrogenation (PDH) to propylene market is projected to reach $22,721.2 million by 2031 from $10,314.6 million in 2022, growing at a CAGR of 9.2% during the forecast period 2022-2031.

Propane Dehydrogenation to Propylene Overview

Thermosets are polymers that, when cured through heat or chemical reactions, become rigid and maintain their shape permanently.

The very feature that makes thermosets desirable for applications requiring durability is also what makes them difficult to recycle. Traditional thermoset plastics cannot be reshaped or reprocessed once cured because the cross-linked molecular structure prevents them from being melted down.

Applications for Propane Dehydrogenation to Propylene Market

1 Automotive and Aerospace: These industries rely heavily on thermoset composites for lightweight, high-strength materials that improve fuel efficiency and performance.

2 Electronics: Thermoset plastics are commonly used in electronic components due to their excellent insulating properties.

3 Construction: Thermosets are used in construction materials such as adhesives, coatings, and insulation.

Market Segmentation

1 By End Users

2 By Technology

3 By Derivative

4 By Region

Download the report and get more information @ Propane Dehydrogenation to Propylene Market

Major Key Players

LyondellBasell Industries Holdings B.V.

Borealis AG

Williams

INEOS Group Limited

GAIL (India) Limited

Jinneng Science and Technology Company Limited

Dow Chemical Company

Koch Industries, Inc.

And many others

Download the sample page click here @ Propane Dehydrogenation to Propylene Market

Demand – Drivers and Limitations

Following are the demand drivers for the global Propane Dehydrogenation to Propylene market:

• Advancement in Thermoset Recycling Technologies Globally • Regulations Promoting Plastic Recycling in Various Countries • Investments and Collaboration in Plastic Recycling Industry

The following are the challenges for the global Propane Dehydrogenation to Propylene market:

• Complex Process of Thermoset Recycling • Lack of Proper Infrastructure for Hard-to-Recycle Products

Recent Developments in Propane Dehydrogenation (PDH) to Propylene Market

• In March 2022, KBR and ExxonMobil Catalysts and Licensing collaborated on the advancements of propane dehydrogenation (PDH) technology. Under the collaboration, ExxonMobil's proprietary catalyst technology would be combined with KBR's proprietary K-PRO PDH technology to convert propane into propylene.

•In January 2022, Hyosung Chemical started the production of propylene by PDH technology for the production of polypropylene units. Before the start-up of this plant, the polypropylene units were dependent on imported propylene.

Conclusion

The propane dehydrogenation (PDH) market for propylene production is positioned for significant growth, driven by the rising demand for propylene across various industries, including packaging, automotive, construction, and textiles.

Overall, the PDH market is poised for expansion, supported by the growing demand for propylene in emerging economies, continued advancements in PDH technology, and a global push towards more energy-efficient and cost-effective chemical processes

0 notes

Text

Personal Computing Procurement Intelligence 2024-2030: Uncovering Hidden Opportunities

Procurement of personal computing services refers to the process of acquiring computers, related hardware, and software for individual use or within an organization. The global market size was estimated at USD 205.5 billion in 2023. Efficient procurement ensures optimal performance, cost-effectiveness, and compatibility with existing systems while maintaining a focus on security and user satisfaction. In 2023, North America held the largest share of the global market with 30%. This growth can be attributed to the dominating presence of key players, deployment of high-speed data infrastructure, advancements in laptop design and performance, innovation and sustainability initiatives by key players, and an increase in sales via e-commerce platforms.

Asia Pacific is poised to witness the fastest growth rate during the forecast period due to the rise of commercial establishments, rapid infrastructure development, surge in product usage by emerging economies, capacity expansions by key suppliers, improvements in technology, and an increase in government initiatives. Key countries driving the growth in Asia Pacific include China, India, Vietnam, Malaysia, and Taiwan, owing to efficient and low-cost production facilities, cheap costs of labor, and components such as semiconductors, and high demand growth from various commercial units.

These products are deployed by a wide range of end-users to execute a wide spectrum of day-to-day tasks, enable efficient administration, enhance employee productivity, and improve time management. Key end-users include corporate offices, educational establishments, government agencies, finance and accounting companies, and other sectors such as healthcare, hospitality, and retail. For instance, finance and accounting firms utilize these products for financial analysis, budgeting, and tax preparation. Government agencies use these products for managing public records.

Order your copy of the Personal Computing Procurement Intelligence Report, 2024 - 2030, published by Grand View Research, to get more details regarding day one, quick wins, portfolio analysis, key negotiation strategies of key suppliers, and low-cost/best-cost sourcing analysis

Key technology trends impacting the growth of this industry include thin clients, Organic Light-Emitting Diode (OLED) panels, convertible 2-in-1 Designs, AR and VR integration, and slim and lightweight design. Convertible 2-in-1 designs enable products to seamlessly transform between two modes such as laptop and tablet. These designs have hinges that facilitate a 360-degree rotation, enabling users to switch effortlessly. In laptop mode, these products have a physical keyboard and trackpad for efficient typing and multitasking. When detached from the keyboard, they are converted into lightweight tablets, suited for on-the-go use. These convertible products are also equipped with touchscreens, making them ideal for note-taking, drawing, and navigating applications.

Key suppliers that provide personal computing items compete based on product pricing, customization, compliance with environmental standards, lead time optimization, innovation in design aspects, and improvement of security options. Buyers in this market have diverse options for budget range, product specifications, supplementary services, product warranty, and after-sales options. Regulatory directives in several countries require suppliers to comply with stringent standards related to product durability, quality standards, safety measures, waste recycling, and environmental impact.

The prices of these products are impacted by numerous variables. Key elements affecting the prices include variations in the prices of raw materials and components, supply chain and logistical issues, labor cost fluctuations, and licensing and compliance needs. Commonly used raw materials such as plastic, glass, metals, aluminum, arsenic, and silicon undergo significant variations based on feedstock and energy costs. On a similar note, costs of components such as semiconductors, batteries, and motherboards may fluctuate due to several reasons.

For instance, in 2023, key manufacturers faced a major challenge in the form of semiconductor and chip shortages due to supply disturbances. These disruptions were driven by geopolitical conflicts and the U.S. sanctions on Chinese suppliers amid a tech war between the two nations. The increases in chip prices in turn had made the electronics and computing products very expensive in 2021 and 2022. The prices of semiconductors also increased to meet the growing demand for people worldwide. Similarly, aluminum is widely used in this sector, such as casing devices, computer parts, power lines, etc. Between July 2023 and January 2024, the global aluminum prices increased from USD 2,160 per MT to 2,201 per MT mainly due to increased demand in battery packs and casing. As a result, prices of products such as laptops / desktops also slightly increased.

The COVID-19 pandemic caused a substantial transformation in this industry. During the pandemic, demand for these items from corporate offices increased considerably, to facilitate remote working trends such as virtual meetings and uninterrupted communication in work-from-home conditions. On a similar note, demand for these products from educational institutions also increased, to facilitate the increased requirement for conducting online lectures and using e-learning platforms.

Post the pandemic, key suppliers are catering to changing customer demands by providing enhanced security features, investing in innovative product design, optimizing product performance, improving screen resolution, and extending battery life in these products. For instance, in 2023, suppliers such as Dell, HP, and Apple launched a new series of laptops with design innovations, upgrades in processing speed, and superior display resolutions. In procurement, the best practices for finding suppliers include comparing pricing options, evaluating product specifications, assessing suppliers' experience levels, analyzing client feedback, evaluating service capabilities, and comparing lead times.

Personal Computing Sourcing Intelligence Highlights

• The personal computing market comprises a fragmented landscape, with suppliers engaged in intense competition.

• Due to the vigorous market competition, buyers within the industry have significant bargaining power and have the flexibility to switch to better alternatives.

• China and the U.S. are favored as low-cost or best-cost countries within their respective regions for sourcing personal computing products due to their reasonable costs of low costs of electronic components and the presence of well-established manufacturing units.

• The key cost components include raw materials and electronic components, labor, equipment, packaging and labeling, logistics and supply chain, and other costs. Other costs include R&D, rent and utilities, licensing and compliance, sales and marketing, general and administrative, and taxes.

Browse through Grand View Research’s collection of procurement intelligence studies:

• Digital Procurement Systems Procurement Intelligence Report, 2023 - 2030 (Revenue Forecast, Supplier Ranking & Matrix, Emerging Technologies, Pricing Models, Cost Structure, Engagement & Operating Model, Competitive Landscape)

• Direct Mail Services Procurement Intelligence Report, 2023 - 2030 (Revenue Forecast, Supplier Ranking & Matrix, Emerging Technologies, Pricing Models, Cost Structure, Engagement & Operating Model, Competitive Landscape)

Personal Computing - Key Suppliers

• Acer Inc.

• Apple Inc.

• ASUSTeK Computer Inc.

• Dell Inc.

• HP Development Company, L.P.

• Huawei Technologies Co., Ltd.

• Lenovo Group Ltd.

• LG Electronics Inc.

• Samsung Electronics Co., Ltd.

• Sony Group Corporation

Personal Computing Procurement Intelligence Report Scope

• Personal Computing Market Growth Rate: CAGR of 7.2% from 2024 to 2030

• Pricing Growth Outlook: 5% - 10% increase (Annually)

• Pricing Models: Cost-plus pricing, competition-based pricing, bundled pricing, demand-based pricing, penetration pricing

• Supplier Selection Scope: Cost and pricing, past engagements, productivity, geographical presence

• Supplier Selection Criteria: Geographical service provision, industries served, years in service, employee strength, revenue generated, key clientele, regulatory certifications, product range, processor type, storage type, use of sustainable materials, delivery mode, customer service, and others

• Report Coverage: Revenue forecast, supplier ranking, supplier matrix, emerging technology, pricing models, cost structure, competitive landscape, growth factors, trends, engagement, and operating model

Brief about Pipeline by Grand View Research:

A smart and effective supply chain is essential for growth in any organization. Pipeline division at Grand View Research provides detailed insights on every aspect of supply chain, which helps in efficient procurement decisions.

Our services include (not limited to):

• Market Intelligence involving – market size and forecast, growth factors, and driving trends

• Price and Cost Intelligence – pricing models adopted for the category, total cost of ownerships

• Supplier Intelligence – rich insight on supplier landscape, and identifies suppliers who are dominating, emerging, lounging, and specializing

• Sourcing / Procurement Intelligence – best practices followed in the industry, identifying standard KPIs and SLAs, peer analysis, negotiation strategies to be utilized with the suppliers, and best suited countries for sourcing to minimize supply chain disruptions

#Personal Computing Procurement Intelligence#Personal Computing Procurement#Procurement Intelligence#Personal Computing Market#Personal Computing Industry

0 notes

Text

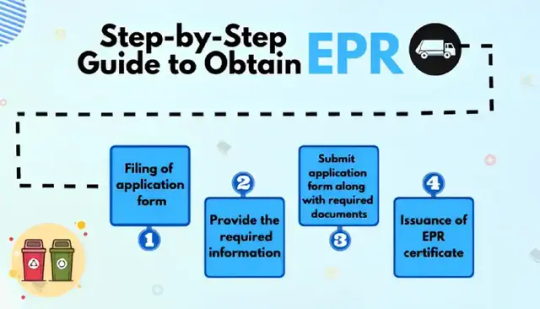

What is EPR and How to Get an EPR Certificate?

Extended producer responsibility or EPR services in India is a policy introduced by the government to handle plastic waste management. It binds the producers, importers, dealers, brands, and e-retailers to dispose of plastic and e-waste as per world standards. The policy is designed by the Central Pollution Control Board (CPCB). The CPCB EPR list is published on their website to regulate the process.

What is EPR Certificate?

An EPR certificate is a mandate across various countries. This reduces the excess burden on municipal bodies and local agencies for plastic disposal and recycling. Plastic waste management is becoming a challenge as plastic products are integral to everyday life. It is impossible to eliminate such products; thus, recycling items into new usable products is a better alternative.

The EPR certificate for plastic waste in India confirms that the organization or business meets all the requirements stated for EPR compliance. It states that the company is absorbing and recycling an equal amount of plastic it introduces into the environment. Achieving a circular cycle in the plastic economy is a requisite and needs to be taken seriously.

How to get an EPR Certificate?

As EPR has been made compulsory for all business types and sizes using plastic in any form, many organizations are joining the initiative. This has led to the need to standardize the collection and recycling process to ensure that the products received post-recycling are of high quality and can be used without any health hazard to the end consumer.

Any organization seeking an EPR certificate for plastic waste in India must fulfill the requirements and submit appropriate documentation. Below are some major points to be considered when applying for EPR registration with CPCB:

1. Details of the authorized person from the company, like name, registered address, contact details, fax number, e-mail, Aadhaar card, signature, etc., in JPG file format.

2. IEC certification and GST certificate of the organization.

3. Udyam license.

4. CIN number.

5. Details of plastic products used and recycled by the company.

6. Sales report with the state-wise breakup.

7. Capital investment devoted to the EPR services in India.

8. Financial statements establishing the sales in KG or tonnes in the last two years of operations.

9. Detailed plan stating measures and processes followed for recycling plastic waste.

10. Documents stating compliance as per local and national laws.

A Brief Process for EPR Registration with CPCB.

To have a smooth registration process, every organization should first understand how to get an EPR certificate. Below are the steps a novice should consider:

1. Identify the government agency that deals with EPR in India:

EPR in India was introduced in 2016. Since then, the government has been transforming the policy to achieve the desired goals in plastic waste management.

A company that decides to begin with plastic recycling should first know details about the government agency that handles this segment. The central pollution control board decides and monitors EPR in our country. Making it to the CPCB EPR list before commencing with the recycling services is necessary.

2. Understand the requirements:

The CPCB has clearly stated the documents and information required for the EPR certification. It is vital to understand the requirements before starting the registration process. Hence, an in-depth study of the CPCB website is a must.

3. Gather the documents:

The government is strict and serious about EPR implementation and accepts applications that meet the criteria. So, the company should carefully gather the documents stated on the website and ensure that the information shared by them is true. Any inconsistencies may lead to the dismissal of the application.

4. Submission:

Details like waste recycling plans help CPCB to know if the company understands what EPR is all about and the legalities involved. Audit reports, financial statements, and legal documents are all part of the submission. The board evaluates the application and then issues the certification. Thus, transparency of each company detail is crucial.

Key Takeaways

It is quite significant to have an acquaintance of the needs stated by an EPR agency to qualify for EPR services in India. It is necessary to avoid any inaccuracies when applying for the EPR certification and registration. CPCB closely monitors every organization even after the certificate is issued and demands detailed reports confirming the successful implementation of EPR services. Attaining a circular cycle in the plastic economy is essential and requires to be taken seriously.

0 notes

Text

Recycling is a good way to reuse plastic products but our world is at a point where we need to remove plastic completely in order to save our earth.

EPR for Plastic Waste Registration is something that is highly needed by all the importers Brand Owners and Producers throughout India. EPR for Plastic waste means all the plastic Products which we use in our day-to-day life produce waste on a massive level. Plastic waste in today’s world is nearly about 5.6 million tons per annum but there is no proper way to dispose of this huge amount of waste to date which causes a big issue for the environment and therefore, for our survival. To know more and get EPR license click here https://arkcacorporate.com/pollution-control-board/epr-for-plastic-waste/

Contact us for more details: Phone number - 9316631170 Email - [email protected] Or visit our website: www.arkcacorporate.com Regards Team ARKCA

1 note

·

View note

Text

Price: [price_with_discount] (as of [price_update_date] - Details) [ad_1] Designed for good - A promise of sustainable and ethical production: uppercase is committed to partnering with you in building a world more beautiful. All our products are made from sustainable materials and are GRS (Global Recycle Standard) certified. GRS is intended for use with any product that contains at least 50% Recycled Material (License No. CMPY-158596). Not only that, but our manufacturing processes also conform to the highest and most stringent GRS criteria. We ensure fixed working hours, minimum wages, and no child labour. We maintain strict standards in factory safety, energy management, and waste disposal management. We do not use any restricted or harmful chemicals. Every Topo luggage bought helps reduce 17.5 1-litre plastic bottles from the planet, helps conserve 223ml of crude oil, and prevents 1113g of CO₂ emission. Product Dimensions : 39 x 26 x 57 cm; 3.1 Kilograms Date First Available : 30 August 2022 Manufacturer : Acefour Accessories Pvt. Ltd. ASIN : B0BCH3S87W Item model number : 5700EST1BLU Country of Origin : India Department : Unisex Adult Manufacturer : Acefour Accessories Pvt. Ltd., Acefour Accessories Pvt. Ltd. , Lodha Supremus Corp. Tower, Unit 1202,12th Floor,Saki Vihar road, Chandivali, Tunga Village, Opp. MTNL office, Andheri E, Mumbai -400072, Maharashtra, India Packer : Acefour Accessories Pvt. Ltd Item Weight : 3 kg 100 g Item Dimensions LxWxH : 39 x 26 x 57 Centimeters Net Quantity : 1.00 count Generic Name : Luggage- Suitcase Suitcase has premium push button trolley; There is bottom handle in this bag to easily lift your luggage along with a full expander for additional space; Separate shoe and shirt packing cubes help you organise your bag in an efficient way There is quick access front pocket in front of this luggage bag for last minute packing and a keyless TSA approved lock security system. Suitcase has a dust resistant body and there are corner and kick guards for extra protection; Cushioned integrated top and side handles makes this trolley bag your comfortable and perfect travel partner GRS certified for sustainability; Made from premium recycled water-resistant material; 2500-Day international warranty Lock Type: Combination Lock; Department Name: Unisex Adult; Material Type: Polyester; Shell Type: Soft [ad_2]

0 notes

Link

The E-waste management system is the prominent focus of various Public and private entities looking at the huge increment in the use of electronic gadgets, the Indian government has initiated several initiatives throughout the Nation, such as Clean India and Smart Cities Mission, Digital India, etc. through the government focus and promotion the generality get the idea of E-waste Management process.

#central pollution control board certificate#cpcb plastic waste registration#cpcb stands for central pollution control board#cpcb certificate verification#cpcb registration portal#e waste registration#e-waste recycling license in india#e scrap certificate#e-waste certificate#e waste licence in haryana#e waste disposal certificate#e waste license#cpcb license

0 notes

Link

A significant environmental issue harming our world is plastic waste. Our oceans, landfills, and even our air have all been contaminated by the careless disposal of plastic refuse. Given that a sizable portion of the waste stream in India is made up of plastic waste, the issue is especially acute there.

#plastic waste management authorization#plastic waste management registration#plastic recycling License#plastic recycling certification#plastic recycling certification in india#plastic waste management registration online#plastic waste management rules#plastic recycling License in india#plastic waste recycling license

0 notes

Text

The Waste to Compost project

Land filling, incineration and recycling 4% are presently being used but they do not resolve the problem of environmental damage caused by plastic. Representatives of the State Bank of India acknowledged that the project is already running on profit, thus proving the efficiency of the method. The initiator of the project will bring all the technology and equipment necessary for the setting of the pilot plant while the government, in collaboration with Green Hydrocarbons Ltd. Actually India sells its hydrocarbon at 40% to 50% less than normal diesel. Moreover, plastic can only be recycled three to four times, after that it loses its strength and can’t be recycled. The pilot project will hence be converting some.

Now just imagine a process able to clear our environment of plastic wastes, creating jobs in waste management and collection and at the same time bringing useful resources such as petrol and gas, which can be beneficial to our economy. Ltd. The Waste to Compost project, will however give a new dimension to the processing of plastic in that hydrocarbon and the other by-products used as compost.. The technology is presently being exported to other regions such as Rajasthan and even to America; for instance, some hospitals are being operated using their own wastes. She asked for analysis by Indian Oil and made a number of recommendations for the use of the final products.

This project has enabled India to better manage the country’s plastic wastes while at the same time creating jobs. The world produces no less than 60% more plastic wastes than it did some ten years back with a production of 100 million tons every year.According to the report from the Ministry of environment, Mauritius produces some 120 tons of plastic wastes daily amounting to a total of 43,800 tons of waste every year of which only 4%, representing some 164 tons, are recycled.5 tons of plastic wastes daily into some 25,000 liters of petrol and other by-products.

This project is a green alternative to the palliative solutions that have been found so far to deal with plastic wastes. Pvt. While giving a lecture on Applied Chemistry, she came up with the idea of turning plastic back into hydrocarbons. India produces 10,000 tons of plastic wastes everyday which 40% are recycled., will provide the necessary location and licenses. The project realized with the collaboration of Indian partners is due to start in the course of the year 2007, once the EIA obtained.Recycling is unfortunately not a practical solution in that the cost of collection is quite high; there is a limited market for it, with an absence of marketing.

The process was later extended to treat 25,000 tons daily in 2006 and the objective of the project is to treat some 450,000 tons. Land filling, incineration, recycling, gasification and blast furnace have shown their limits in the treatment of plastic wastes. In 2006, the population’s consumption of non-biodegradable plastic products amounted to some 70 million Polyethylene Terephthalate (PET) bottles, 7 million PVC bottles, and 113 million plastic bags. Pvt. The Liquid Hydrocarbons pilot project proposed by the Green Hydrocarbons (Mtius) Ltd has the ambitious desire of turning our plastic wastes into hydrocarbon petrol.The investments for the pilot project in Mauritius are estimated to around 100 to 300 millions Rupees.After about one year of operation, the project was realized with the help of loans. Ltd of India later launched a pilot project where some 5,000 tons of plastic wastes were converted everyday.Unique Waste Plastic Management & Research Co.

She worked with a team on the formula and in 2004; they succeeded in turning 300mg of plastic into hydrocarbon liquids., will enable Mauritius to get rid of its plastic wastes while at the same time providing resources such as petrol.The environment friendly project, realized with the collaboration of the initiators of the project China Plastic Beer Crate Mould in India, Unique Waste Plastic Management & Research CO. The ratio of the conversion of the plastic waste into petrol is one kilogram of plastic into the volume of 1000 cc of petrol. BeginningsThe concepts of plastic conversion into hydrocarbons was elaborated by Professor Alka Zadgaonkar of the Raisoni College of Engineering, Nagpur in Indian, in the year 1995

0 notes

Text

Extended Producer Responsibility

Extended Producer Responsibility (EPR) is an important policy mechanism that helps promote the circular economy and reduce the environmental impact of products and their packaging. In addition, we promote the polluter pays principle by taking responsibility for the entire product life cycle.

EPR is met by the manufacturer by reusing, buying back, or recycling discarded products. The manufacturer also has the option of delegating this responsibility to a third party that the manufacturer can pay for lifespan management. This shifts the responsibility for waste management from the government to the private sector, making it easier for manufacturers or distributors to internalize waste management and ensure the safe handling of their products.

The Ministry of Environment, Forestry, and Climate Change has announced Extended Producer Responsibility Guidelines for Plastic Packaging under the 2016 Plastic Waste Management Regulations to reduce pollution caused by domestic plastic packaging waste.

· Strengthening the Circular Economy: The guidelines provide a framework for strengthening the circular economy of plastic packaging waste. The guidelines require the reuse of rigid plastic packaging materials to reduce the use of unused plastic materials in packaging.

· Reduce plastic consumption: The policy requires a minimum level of recycling of plastic packaging waste collected as part of the EPR and the use of recycled plastic contents. It further reduces plastic consumption and supports the recycling of plastic packaging waste. Companies will collect at least 25% of the target by 2021-22, 70% by 2022-23, 100% by 2024, 30% to 50% of waste by 2024-2025, 60% to 80 by 2027-28. % Need to be reused.

· Push Formalization: EPR guidelines support the formalization and further development of the plastic waste management sector. The guidelines allow the sale and purchase of surplus Extended Producer Responsibility Certificates and create a market mechanism for the disposal of plastic waste

· Improving the efficiency of EPR governance: EPR implementation is done through a bespoke online platform that acts as the digital backbone of the system. The online platform enables tracking and monitoring of EPR obligations, reducing the burden of corporate compliance. To ensure compliance with EPR obligations, the Directive mandates a system for reviewing and auditing companies.

· Implementation of the Polluter Pays Principle: The guidelines provide a framework for imposing environmental penalties based on the Polluter Pays Principle if the Extended Producer Responsibility Goal fails to be achieved.

The latest new Extended Producer Responsibility (EPR) policy is the first step in the right direction to improve producer accountability and regulatory enforcement. However, the informal sector waste recycling business is not licensed or regulated, and compostable or biodegradable plastics are not subject to the new guidelines. These issues need to be addressed in order to fully achieve the goals of plastic waste management in India.

0 notes

Text

Why is it Obligatory to Get an EPR Certificate in India?

Waste management is a challenge that governments across the globe are dealing with. Unimaginable dumping of plastic products and e-waste is an urgent issue that needs to be addressed; hence, EPR services have emerged as a crucial tool. Initially, few countries introduced EPR, a voluntary practice for producers, plastic product importers, and brand owners. But with time, governments introduced it as a mandatory practice to ensure better results and cumulative efforts from all sectors.

Implementation of Extended Producer Responsibility (EPR) :

2016 was the year when the groundwork for the implementation of Extended Producer Responsibility (EPR) in India began. Today, we have a well-defined framework for the policy, and companies from all sectors actively participate. With the quick industry and organizational growth, it becomes essential to regulate the process; thus, an EPR certificate is obligatory. Organizations that wish to join this drive against plastic pollution should first understand what is an EPR certificate and the benefits of an EPR certificate.

What is an EPR certificate?

EPR certificate permits brands and organizations to practice plastic waste recycling and management process following set guidelines. Therefore, one of the most important advantages of the EPR certificate is that the yields received post-recycling are of good quality and can be easily used in manufacturing new, usable products. It is essential to understand that plastic waste can only be managed by attaining a circular economy, which means that plastics do not leak into the natural environment. This is also referred to as ‘upstream recycling.’ Initially, when the Indian government introduced this policy, there were several questions regarding the relevance of plastic recycling. There were several questions about the sustainability of the recycling process, the benefits companies would get, and what is an EPR certificate. However, with time organizations understood how to contribute to a better environment and simultaneously benefit their businesses. As a result, today, extended producer responsibility (EPR) services in India are a huge success, and more organizations are joining the league.

Approaches of Practicing EPR Services in India:

There are three ways in which companies can practice extended producer responsibility (EPR) services in India. These are:

1. Fee-based EPR: This model is best suited for small industries. Here, they need to pay an EPR fund that will be used to manage the plastic waste recycling process.

2. PRO-based EPR: An organization that does not know how to get an EPR certificate and wants to avoid the extra cost of setting up a recycling plant can use the PRO model. They either partner or hire with the producer responsibility organization (PROs). A PRO is well-equipped and proficient in managing waste.

3. Plastic credits-based EPR: Some organizations become part of the EPR services by collecting and supplying plastic waste to the recycling units. In this process, they are awarded plastic credits.

Documents needed for EPR Certification:

EPR license is a must for PIBOs. The government has laid clear guidelines on how a company can obtain the certification. Here is a detailed guide on how to get an EPR certificate:

Office address proof and contact details

A certificate stating the details of incorporation and directorate

Details of importers like IE code

Municipal corporation licenses and agreements.

Copies of the signatory’s PAN and Aadhar

Product details being manufactured by the company

Copy of BIS license with ROHS compliance

Estimate of plastic or e-waste generated at the facility

EPR budget

Agreements signed with waste management organizations and recyclers.

Detailed plans describing awareness programs run by the company

Companies that understand the benefits of EPR certificates submit the right information without any discrepancies. The process can be completed online with the least effort and time.

Key Takeaways:

It is crucial for Producers, Importers & Brand Owners (PIBOs) to have EPR Registration, Certification as well as Compliance. Since the government has been rigorously working to ensure the successful implementation of extended producer responsibility in India, organizations must join hands and support the cause. EPR is not confined to the advantages of an EPR certificate or monetary benefits companies get from using recycled plastic. Still, it has a massive impact on nature and the future of humans. It is an obligatory movement against plastic waste to save our future. Reach out to our experts today to get started with EPR registration.

0 notes

Text

Tire Material Market Size Forecast to Reach $77.46 Billion by 2025

Tire Material Market size is forecast to reach $77.46 billion by 2025, after growing at a CAGR of 3.57% during 2020-2025. Using hydraulic power brakes and other movement-control technology in cars, high-performance tires are required. In addition, the need for vehicle containment and traction has shifted the emphasis towards black carbon, wire, and synthetic rubber for tire manufacture. The automotive industry has exercised caution when it comes to evaluating the consistency of the products used for tire manufacturing owing to which it will further accelerate the growth of the Tire Material industry in the forecast era.

Type - Segment Analysis

Elastomer is widely used in Tire Material Market. Elastomeric tires through high tech natural rubber tread compounds are engineered to achieve low rolling resistance, high abrasion, and longer wear. The high tensile and tear properties of this tread formulation ensure good efficiency in the toughest applications. The mid-layer cushion of the tire is built to match tire strength and hardness perfectly. This balance is crucial for maintaining "low rolling" resistance while maximizing the efficiency of the shock absorption. The natural rubber tread compound covers the middle layer, reducing sidewall damage. The product for the tire base or heel is formulated with materials lined with strong rubber fiber. Also, elastomer has good building tack, excellent extrudability, and calendar ability, high rate of cure, and storage hardening due to which the demand for tire materials is foreseen to increase over the forecast era.

Request for Sample of the Report @ https://www.industryarc.com/pdfdownload.php?id=500070

Report Price: $ 4500 (Single User License)

Vehicle Type - Segment Analysis

Passenger car held the largest share in Tire Material Market in 2019 and is projected to grow at a CAGR of 4.14% during the forecast period 2020-2025. Tires are primarily built for harsh terrain and heavy loads. The most popular vehicles on the highway are the cars and light-duty trucks used for passenger transport. A tire is primarily built in passenger cars for ride comfort, stability, handling, and wear life as well as appearance and affordability. Tires do have strong mileage scores and give your buck the best bang. All-season tires provide a smooth ride, long-wear, and adequate traction to passenger car even under dry and humid weather. Also, Tires provide a gripping traction surface and serve as a cushion for a moving vehicle's wheel owing to which it has increasing use in passenger cars and is estimated to boost the tire material market in the forecast period.

Geography- Segment Analysis

Asia Pacific held the largest share with 35% in Tire Material Market in 2019. Changing lifestyles and standard of living have increased the adoption of high-performance tires as well as branded tires, also expected to positively impact the tire materials market in the Asia Pacific region. The increasing number of vehicle owners will push the growth of both OEM as well as aftermarket segments, and boost the tire materials market going forward. According to the International Trade Administration, China is the largest vehicle market in the world, with the Chinese government expecting car production to reach 30 million units by 2020, and 35 million by 2025. Also, according to India Brand Equity Foundation in 2018, India became the fourth largest auto market with sales increasing 8.3% year-on-year to 3.99 million units. It was also the seventh-largest manufacturer of commercial vehicles in 2018.

Drivers –Tire Material Market

Increasing the use of green tires in vehicles

Green tire is made from recycled materials like nylon rubber through a process that does not require an excessive amount of energy. Conventional tires are made of rubber, but tires are now often manufactured from sustainable raw materials such as plasticizers and resins, with growing energy concerns. Such environmentally friendly raw materials are increasingly chosen over traditional products due to advantages such as being lighter than traditional products, which results in a reduction of the vehicle's total weight. This also needs less fuel and helps lower the resistance to rolling. During the forecast period, the green tires are expected to witness a lucrative growth rate mainly due to advantages such as long-life and retractable tires. Also, the increase in energy costs, strict government regulations, and increased environmental awareness regarding fuel consumption among consumers will lead towards the increase in the use of green tires in vehicles during the forecast period.

Increasing the production of automotive

The rise in the middle-class population and income has led to the growing demand for automotive in recent years. In addition, the company's growing interest in exploring the rural markets further aided the sector's growth. According to India Brand Equity Foundation, India is also a popular car exporter with high hopes for export development in the near future. During FY19, automotive exports grew 14.50 percent. It is projected to rise during 2016-2026 at a CAGR of 3.05%. However, multiple initiatives by the Government of India and the major car players on the Indian market are expected to make India a pioneer in the two and four wheels. By enabling consumers to travel long distances for work, shopping, and entertainment, the automotive industry has encouraged the development of a comprehensive road system, enabled the growth of suburbs and shopping centers around major cities, and played a key role in the growth of ancillary industries such as oil and travel.

Talk to one of our sales representative about the full report by providing your details in the link below:

https://www.industryarc.com/support.php?id=500070

Challenges –Tire Material Market

Effect of tires to the environment

The enormous amount of solid waste produced from the tire's major concern. Old tires contain heavy metals and chemicals that leach when these tires disintegrate into the atmosphere which is known as leaching. The mutagenic and carcinogenic value of some of these chemicals has been recognized. A further danger faced by leaching is the contamination of the soil. The soil around these old tires can be quickly polluted with the environmentally released harmful chemicals. Even groundwater is at risk of getting polluted. Also, if the water in the soil is tainted by these chemicals, the poisoned water will further come into contact with animals and humans and even endanger their lives. In addition, in the case of discarded tires, one of the key issues is an increased fire risk. For fuel production, almost half of the recycled scrap tire is used. However, it may be more difficult to deal with and extinguish fires that are fuelled by tires.

Market Landscape

Technology launches, acquisitions, and R&D activities are key strategies adopted by players in the Tire Material Market. In 2019, the market of Tire Material Market has been consolidated by the top five players accounting for xx% of the share. Major players in the Tire Material are Cabot Corporation, JSR Corporation, Thai Carbon Black, Bekaert, Lanxess, Royal Dutch Shell, Orion Engineered Carbons, American Zinc Recycling LLC, Exxon Mobil Corporation, DMACK Tyres among others.

Key Takeaways

Asia Pacific dominates the tire material market due to its increasing use of vehicles by a rapidly growing population.

The rising trend of 'green' tire is gaining traction. Automobile manufacturers are urged to produce tires using environmentally friendly materials and methods. Hence, this factor is expected to play a key role in shaping the global tire materials market during the forecast period.

In terms of air, water, and soil contamination, the used tires have a significant negative effect on the environment which in the immediate future can create hurdles in the market development.

Due to the lockdowns to tackle the Covid-19 outbreak, the automotive industry expects a loss of about 750,000 units in production and $2 billion in revenue in 2020-2021.

Related Reports :

A. Tire-Pressure Monitoring Market

https://www.industryarc.com/Report/16379/tire-pressure-monitoring-market.html

B. US Tire Market

https://www.industryarc.com/Report/18522/us-tire-market-research-report-analysis.html

About IndustryARC: IndustryARC primarily focuses on Cutting Edge Technologies and Newer Applications market research. Our Custom Research Services are designed to provide insights on the constant flux in the global supply-demand gap of markets. Our strong team of analysts enables us to meet the client research needs at a rapid speed, with a variety of options for your business. Any other custom requirements can be discussed with our team, drop an e-mail to [email protected] to discuss more about our consulting services.

0 notes

Text

Price: [price_with_discount] (as of [price_update_date] - Details) [ad_1] Designed for good - A promise of sustainable and ethical production: uppercase is committed to partnering with you in building a world more beautiful. All our products are made from sustainable materials and are GRS (Global Recycle Standard) certified. GRS is intended for use with any product that contains at least 50% Recycled Material (License No. CMPY-158596). Not only that, but our manufacturing processes also conform to the highest and most stringent GRS criteria. We ensure fixed working hours, minimum wages, and no child labour. We maintain strict standards in factory safety, energy management, and waste disposal management. We do not use any restricted or harmful chemicals. Every Topo luggage bought helps reduce 22 1-litre plastic bottles from the planet, helps conserve 280ml of crude oil, and prevents 1397g of CO₂ emission. Product Dimensions : 43 x 28 x 68 cm; 3.5 Kilograms Date First Available : 13 September 2022 Manufacturer : Acefour Accessories Pvt. Ltd. ASIN : B0BF4VPHX8 Item model number : 6800EST1RED Country of Origin : India Department : Unisex Adult Manufacturer : Acefour Accessories Pvt. Ltd., Acefour Accessories Pvt. Ltd. , Lodha Supremus Corp. Tower, Unit 1202,12th Floor,Saki Vihar road, Chandivali, Tunga Village, Opp. MTNL office, Andheri E, Mumbai -400072, Maharashtra, India Packer : Acefour Accessories Pvt. Ltd Item Weight : 3 kg 500 g Item Dimensions LxWxH : 43 x 28 x 68 Centimeters Net Quantity : 1.00 count Generic Name : Luggage- Suitcase Suitcase has premium push button trolley;There is bottom handle in this bag to easily lift your luggage along with a full expander for additional space; Separate shoe and shirt packing cubes help you organise your bag in an efficient way There is quick access front pocket in front of this luggage bag for last minute packing and a keyless TSA approved lock security system. Suitcase has a dust resistant body and there are corner and kick guards for extra protection; Cushioned integrated top and side handles makes this trolley bag your comfortable and perfect travel partner

GRS certified for sustainability; Made from premium recycled water-resistant material; 2500-Day international warranty [ad_2]

0 notes

Photo

plastic waste management is an initiative that aims to establish environment-friendly plastic waste disposal solutions. In the process, it seeks to ban the use of plastic bags and plastic products and reduce plastic littering across the state. Corpseed ITES Pvt Ltd is the best registration/certificate and license service provider with the lowest price. If you have any query related to plastic waste management certificate you contact corpseed company at 7558 640 644. We are available 24*7 for your help...

#epr plastic#epr for plastic waste#plastic waste management#plastic permit#plastic recycling license#epr certificate for plastic waste#plastic waste registration#plastic recycling license india

0 notes